The mining industry is experiencing a seismic shift. As global demand for critical minerals like lithium, cobalt, and rare earth elements surges, the sector faces mounting operational pressures. Among the most pressing challenges is a widening labor gap—exacerbated by an aging workforce, dwindling interest from younger generations, and increasingly hazardous work environments. Fortunately, the emergence of Artificial Intelligence (AI) presents a compelling solution to this workforce crisis and opens the door to AI mineral exploration strategies that redefine efficiency.

The Labor Gap Crisis in Mining

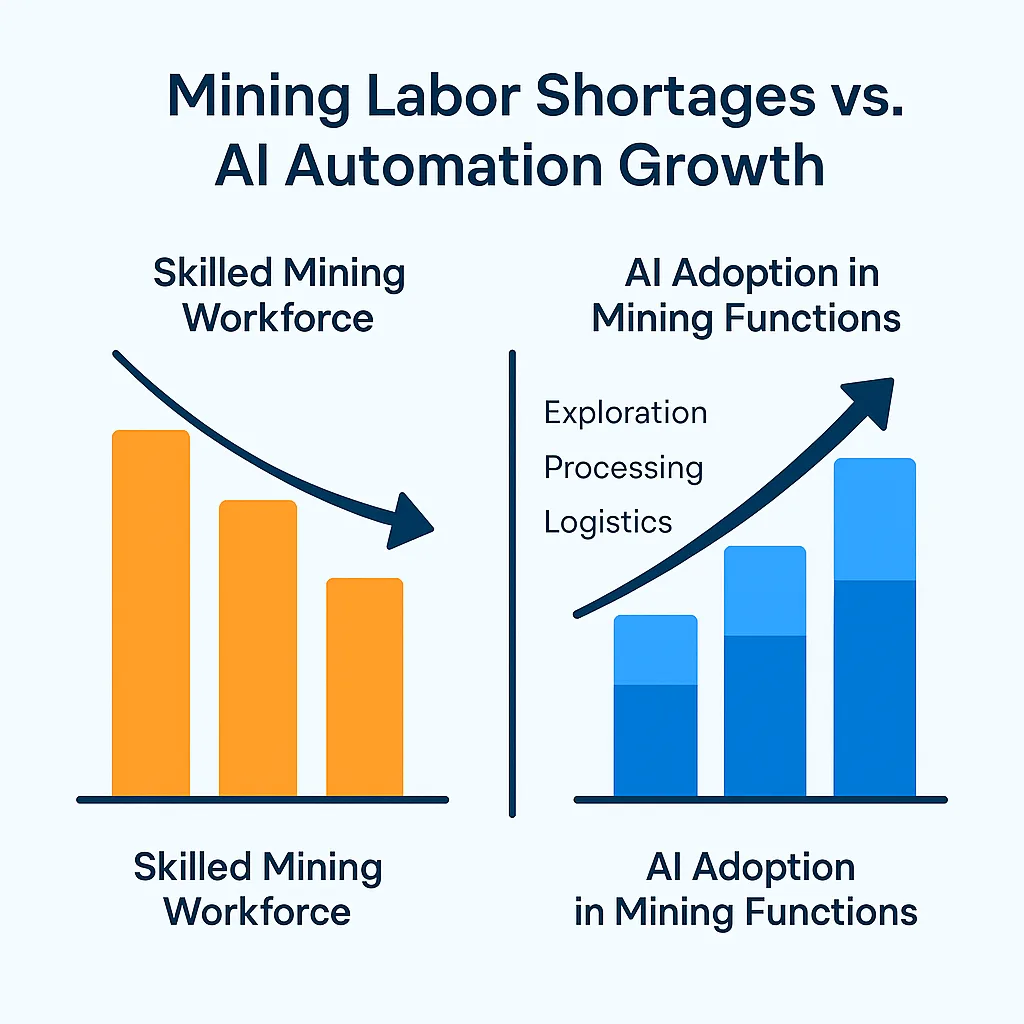

The mining industry has long been associated with physically demanding and often dangerous work. However, the sector is now grappling with a structural labor shortage:

- Aging Workforce: A significant portion of skilled mining labor is nearing retirement age, with fewer young workers entering the profession.

- Remote Locations: Many mining operations are situated in geographically isolated regions, making them less attractive to new workers.

- Health and Safety Concerns: Harsh working conditions, including exposure to dust, vibration, and extreme temperatures, deter potential talent.

- Skills Gap: The integration of digital technologies in mining operations necessitates new skill sets that many traditional workers do not possess.

These challenges not only jeopardize productivity and safety but also threaten the continuity of supply chains critical to global energy transitions. Innovative solutions like AI in mining and smart mining operations are proving essential to overcome these obstacles.

Enter AI-Powered Automation

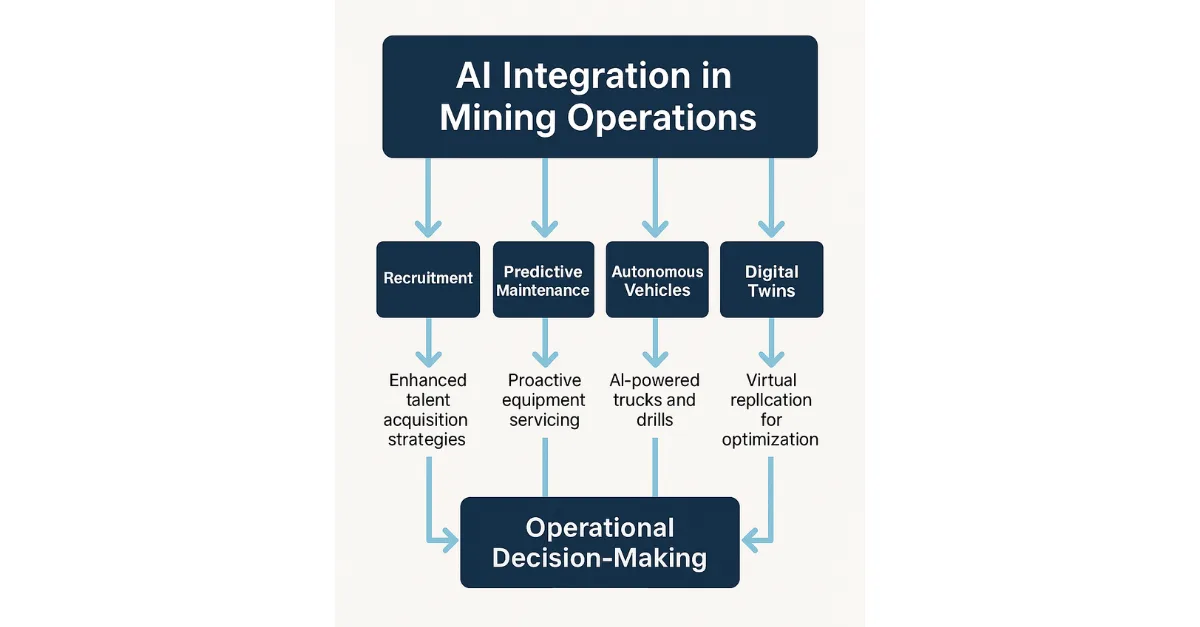

AI-driven technologies are revolutionizing mining operations, offering a path to enhanced efficiency and labor optimization:

1. Autonomous Equipment and Vehicles

Autonomous mining equipment, including AI-powered autonomous haul trucks in underground mining, is now operational in some of the world’s most advanced mining sites. These machines operate 24/7, under extreme conditions, with no human fatigue—boosting productivity and slashing downtime.

2. Predictive Maintenance and Condition Monitoring

Leveraging AI predictive maintenance in mining, companies can monitor equipment health in real time. Predictive algorithms detect anomalies before breakdowns occur, reducing maintenance costs and minimizing the need for on-site labor.

3. Remote Operation & Digital Twins

With the rise of digital twins mining, remote operation centers can simulate and control physical mining environments from afar. This not only enhances safety by removing workers from high-risk zones but also improves accuracy in extraction and logistics planning.

4. Workforce Optimization and Smart Recruitment

AI tools support intelligent workforce planning by analyzing labor trends, retirement risks, and required future skill sets. How intelligence systems address mining labor shortages is becoming a central theme in HR strategies across the industry, enabling the development of more effective training and recruitment pipelines.

Case in Point: Rio Tinto’s Autonomous Success

Rio Tinto, a global mining leader, operates one of the largest fleets of autonomous haul trucks in Australia’s Pilbara region. These vehicles are part of the company’s broader Mine of the Future initiative, which aims to increase efficiency, reduce environmental impact, and address workforce shortages. Their autonomous fleet has delivered productivity increases of up to 15%, while reducing fuel usage and maintenance costs—highlighting the power of mining automation.

Challenges to Consider for AI Mineral Exploration

Despite its promise, AI automation in mining presents several challenges:

- High Capital Costs: The initial investment in AI mineral exploration technologies and autonomous systems is substantial.

- Cybersecurity Risks: Digitized infrastructure can be vulnerable to breaches if not adequately protected.

- Cultural Resistance: Shifting from traditional operations to AI-led processes demands change management and retraining.

- Ethical Concerns: Automation must be implemented responsibly to avoid displacing communities and local workforces.

A Human-Machine Collaboration Model

The future of mining isn’t about replacing people—it’s about empowering them. Through building a hybrid workforce with AI in mineral exploration, companies can merge human insight with machine precision. AI enables employees to focus on high-value, less hazardous tasks, opening new roles in data science, robotics, and automation engineering.

Reinventing the Mining Supply Chain

AI also enhances mining supply chain resilience, enabling real-time tracking, demand forecasting, and inventory optimization. These capabilities are critical in a volatile global market where disruptions can cascade quickly.

A Smarter, Safer Future with BeamData

AI for mineral exploration is more than a buzzword—it’s a catalyst for sustainable transformation. As labor shortages persist and the demand for critical minerals grows, the intelligent deployment of AI in mining will be pivotal. From autonomous mining equipment to digital twins mining, the integration of smart technologies offers scalable solutions to longstanding industry pain points.

In the end, bridging the labor gap isn’t about choosing between humans or machines—it’s about building a future where both thrive. By embracing AI in mineral exploration, companies ensure not only operational continuity but a safer, smarter, and more resilient mining ecosystem.

BeamData offers tools that unlock the potential of vast, underutilized operational data. By aggregating sensor readings, equipment telemetry, and supply chain inputs, BeamData’s platform enhances AI mineral exploration, improves predictive maintenance, and supports smart mining operations. Their solutions empower companies to make data-driven decisions, optimize autonomous systems, and address mining labor shortages—all while building more resilient, efficient, and scalable operations.

FAQ: AI & Automation in Mineral Exploration

1. What is AI mineral exploration and why is it important?

AI mineral exploration uses artificial intelligence to analyze geological and operational data, helping mining companies locate mineral deposits faster, more accurately, and at lower cost.

2. How does automation help with mining labor shortages?

Automation reduces reliance on hard-to-fill roles by enabling remote operations, autonomous vehicles, and AI-driven workforce planning, making mining safer and more efficient.

3. What are some examples of AI in mining operations?

Examples include AI-powered autonomous haul trucks, predictive maintenance systems, digital twins, and real-time decision platforms like those offered by BeamData.

4. How do digital twins improve mining productivity?

Digital twins simulate real mining environments, allowing companies to test scenarios, optimize resource usage, and minimize operational risks without disrupting real-world operations.

5. What makes BeamData a valuable partner for B2B mining companies?

BeamData provides AI-powered analytics tailored for mining, helping B2B companies optimize exploration, reduce downtime, enhance safety, and build data-driven, scalable operations.