In today’s volatile manufacturing environment, the performance of your suppliers is more than just a procurement concern—it’s a strategic priority. A single supplier delay or compliance lapse can disrupt production lines, impact customer satisfaction, and cost millions in lost revenue. Traditionally, supplier evaluation has relied on manual scoring systems and subjective assessments, creating inconsistencies and inefficiencies that no longer meet the demands of global supply chains.

AI in procurement introduces a transformative approach. AI driven supplier scoring, part of this broader trend, combines real-time data, predictive analytics, and procurement automation to deliver consistent, accurate, and dynamic insights. In this blog, we explore why now is the critical time for manufacturers to embrace AI-powered supplier evaluation—and how it directly benefits your bottom line.

Understanding the Business Imperative

Supplier performance has a direct impact on multiple key business outcomes—product quality, delivery timelines, regulatory compliance, and ultimately, customer satisfaction. When manufacturers use outdated or manual supplier scoring methods, they often miss early warning signs of vendor credibility issues and underperformance.

This is where AI supply chain optimization plays a critical role. By integrating predictive supplier evaluation and real-time metrics, businesses can proactively assess suppliers, rather than reactively managing problems after they occur. This proactive model aligns closely with dynamic vendor scoring, where supplier ratings adjust continuously based on new data.

The Limitations of Traditional Supplier Scoring

Conventional supplier evaluation models suffer from several flaws:

- Manual Data Handling: Time-consuming and error-prone.

- Static Scoring Systems: Outdated quickly in today’s fast-paced environment.

- Subjectivity and Bias: Inconsistent scoring across teams.

- Lack of Predictive Insight: No ability to forecast risks like supplier bankruptcy or policy violations.

Without tools like supplier risk analytics or vendor risk management, traditional approaches put companies at risk. Modern manufacturing demands adaptive, AI-powered systems that incorporate procurement data analytics to stay ahead of issues before they cause real damage.

What Is AI-Driven Supplier Scoring?

AI-driven supplier scoring is a modern vendor assessment approach that uses machine learning to evaluate suppliers on an ongoing basis. These tools rely on an AI vendor evaluation model to aggregate structured and unstructured data—including delivery records, financial performance, and ESG disclosures.

Key features include:

- Real-Time Data Aggregation

- Predictive Analytics

- Automated Risk Assessment

- Continuous Scoring Adjustments

Such capabilities form the foundation of an AI vendor evaluation scoring model, which learns and adapts over time. It’s not just about past performance but future reliability, driven by intelligent systems.

Strategic Benefits of AI in Supplier Management

AI-based supplier scoring provides multiple benefits:

- Cost Savings: Improved sourcing decisions reduce procurement costs.

- Delivery Reliability: Predictive insights enhance supply chain dependability.

- Compliance Monitoring: AI flags legal and regulatory risks automatically.

- Faster Decision-Making: With dynamic supplier performance metrics, businesses move quicker and smarter.

Executives are increasingly interested in AI vendor scoring model examples because they directly influence the company’s agility and profitability.

AI’s Role in Vendor Risk Management

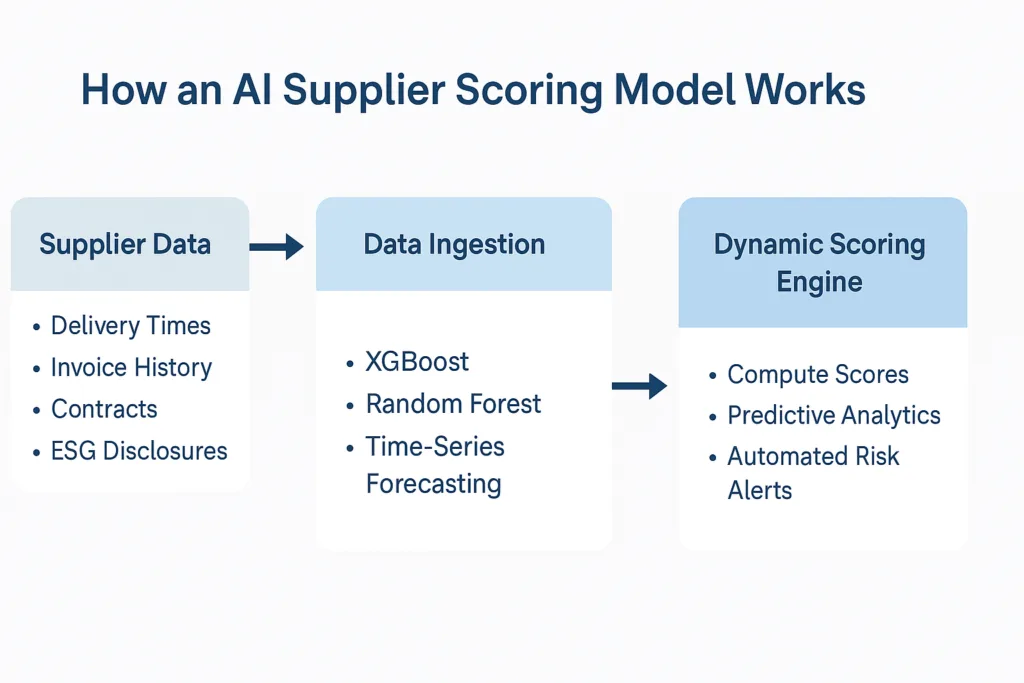

At its core, an AI supplier evaluation platform consists of:

- Data Ingestion: Pulls supplier data from ERPs and external databases.

- ML Algorithms: XGBoost, Random Forest, and time-series forecasting models power predictions.

- Dynamic Scoring Engine: Supplier scores evolve with each data point.

- NLP for Risk Detection: Identifies ESG or compliance issues within documents.

If you’re wondering how to test AI models, the process typically begins with back-testing models on historical data and evaluating accuracy through confusion matrices, precision, recall, and ROC curves.

Real-Time Visibility with AI Dashboards

AI dashboards offer real-time transparency into supplier behavior. These tools—part of next-generation procurement automation—help procurement leaders respond instantly with:

- Live Supplier Scorecards

- Performance Alerts

- Trend Visualizations

With manufacturing supplier scoring now automated, companies can focus on strategic supplier development rather than data wrangling.

Key Metrics to Track Vendor Performance

AI scoring tools don’t treat all data equally. They prioritize metrics like:

- On-Time Delivery

- First-Time Quality Compliance

- Lead Time Variability

- Financial Health

- ESG Performance

These supplier performance metrics feed into predictive models to forecast supplier reliability and flag weak spots in vendor networks.

AI driven Supplier Use Case Spotlight: Before vs. After AI Implementation

Before AI: Quarterly reports missed 15% late deliveries. Compliance violations slipped through, causing fines.

After AI: Real-time analytics flagged delivery volatility and compliance risks. The company renegotiated contracts and saved millions.

Result: $2.8M in procurement savings and approval cycles cut in half.

Such success illustrates the tangible benefits of AI vendor assessment and the power of predictive supplier insights.

Competitive Benchmarking: How AI Gives You the Edge

Adopting AI in procurement gives early movers a distinct advantage:

- Smarter Negotiations

- Lower Risk Exposure

- Superior Sourcing Agility

Many companies struggle to implement full AI scoring frameworks. But with a robust procurement data analytics strategy, your organization can outperform slow-moving competitors still stuck in spreadsheet mode.

Building a Robust Vendor Management Plan with AI

To deploy AI scoring:

- Prepare Data

- Run a Pilot

- Integrate AI Tools with ERP

- Train Procurement Teams

- Scale Intelligently

Each phase builds toward a more intelligent, responsive supply chain.

Overcoming Barriers to Adoption of AI supplier model

Implementation challenges include:

- Data Silos

- System Compatibility

- Change Resistance

- Ethical Considerations

Transparent governance and regular AI audits are essential for maintaining fairness in AI vendor evaluation models.

Leadership ROI: Why Business Executives Should Care

Executives prioritize:

- Faster ROI (6–12 months)

- Reduced Supplier Risk

- Increased Resilience

- Improved Market Positioning

AI helps leaders shift procurement from a cost center to a competitive weapon.

The Roadmap: From Pilot to Full-Scale AI Deployment

1st Phase : Validate your AI vendor scoring model example with past data.

2nd Phase: Link to operational systems and visualize outcomes.

3rd Phase: Expand the model to global sourcing, ESG metrics, and cost optimization.

Empower your vendor management with Beam Data’s differentiated Approach

Beam Data offers a tailored AI scoring solution with:

- Custom AI Models

- Live Dashboards

- NLP-Powered ESG Scoring

- Dynamic Vendor Scoring

Our platform helps companies move beyond off-the-shelf tools to robust, integrated solutions for vendor risk management and real-time supplier scoring.

AI in procurement is not optional—it’s foundational to modern supply chain success. By embedding AI-driven supplier scoring, organizations improve resilience, mitigate risks, and unlock operational efficiencies.

Beam Data stands ready to support your journey with industry-specific models, seamless integrations, and expert guidance.

AI Scoring Vendor Model FAQs

What types of data are required for AI supplier scoring?

Both structured data (delivery records, financials) and unstructured data (ESG disclosures, contracts).

How long does it take to see ROI from AI in supplier evaluation?

Most companies observe measurable ROI within 6 to 12 months.

Is AI supplier scoring suitable for small-to-medium manufacturers?

Yes. Models can be scaled and simplified for smaller operations.

Can Beam Data integrate with existing ERP/procurement platforms?

Absolutely—compatible with SAP, Oracle, Coupa, and others.

How does AI handle ESG and compliance tracking?

Through NLP, scanning documents and external sources for regulatory and environmental risk.