From COVID-19 to geopolitical instability and global material shortages, supply chains have faced relentless disruption. Traditional linear supply models, driven by manual, reactive decisions, have proven vulnerable in this volatile environment.

Today, resilience isn’t optional—it’s mission-critical. Enter AI in supply chain and IoT in supply chain—two powerful technologies whose convergence is reshaping the future of operations. When integrated AI and IoT, they enable real-time supply chain analytics, predictive intelligence, and autonomous decision-making. This article explores how their synergy is creating AI-powered supply chain ecosystems that are intelligent, adaptive, and disruption-resilient.

What is AI and IoT technology?

Artificial Intelligence (AI) uses algorithms to analyze vast datasets, uncover trends, and automate decisions. The Internet of Things (IoT) connects physical assets—machines, vehicles, containers—collecting continuous, real-world data.

Together, they form a robust foundation for the AI and IoT integration now driving modern supply chain transformation. IoT acts as the sensory system, while AI interprets and responds, turning data into actionable insights.

This fusion enables intelligent supply chain technologies that anticipate problems, automate actions, and optimize operations in real time—creating a shift from reactive to proactive supply chain management.

Key Business Benefits of AI & IOT Modern Enterprises

The integration of AI and IoT provides measurable, strategic benefits:

- Real-Time Supply Chain Analytics: Gain 360-degree visibility of goods, assets, and processes.

- Risk Forecasting: Use predictive analytics in supply chain operations to flag potential disruptions before they escalate.

- Cost Reduction: Automate routes, reduce maintenance costs, and optimize labor through smart systems.

- Smarter Decisions: Dashboards consolidate data into digestible insights aligned with business KPIs.

- Sustainability & Compliance: Track emissions, waste, and compliance in real time using sensor-based monitoring.

These advantages strengthen operations and foster long-term competitiveness.

From Reactive to Predictive: Managing Disruption with AI and IoT

Traditional supply chains act after problems occur. But with AI and IoT use cases in manufacturing, issues are detected early and resolved swiftly.

For example, a smart factory supply chain can use vibration sensors and AI models to predict machine failures. Maintenance is scheduled before breakdowns occur. Similarly, AI-driven demand forecasting helps adjust production and logistics to meet evolving market needs, reducing delays and excess stock.

With AI-driven inventory optimization, businesses can maintain optimal stock levels, cut carrying costs, and avoid shortages—even during demand spikes or supply disruptions.

Real World Applications of AI and IoT in Action

Here are some high-impact implementations transforming manufacturing and logistics:

- Predictive Maintenance: AI identifies failure patterns; IoT captures sensor data from equipment in real time.

- Route Optimization: GPS devices and AI collaborate to find cost-effective, on-time delivery routes.

- Digital Twin and AI Supply Chain Models: Virtual replicas simulate and stress-test supply chain responses using real-world data.

- Compliance Monitoring: IoT tracks temperature and humidity for perishables; AI flags deviations to avoid spoilage or regulatory breaches.

- Edge Computing in Logistics: Delivers faster processing for time-sensitive operations, such as on-site defect detection.

Each application enhances performance and resilience by making data a strategic asset.

How does AI and IoT works together?

IoT devices embedded throughout the supply chain collect environmental, positional, and operational data. That data is transmitted to the cloud or edge devices where AI performs:

- Predictive Analytics in Supply Chain: Forecasting equipment failures, demand trends, and delivery delays.

- Real-Time Decision Support: AI systems evaluate data and suggest or execute optimal actions immediately.

- Enterprise IoT Deployment Strategy: Integrates IoT sensors with ERP and MES systems to unify the data landscape.

With edge computing, critical decisions happen near the source, enabling ultra-low latency responses while the cloud provides scalable insights.

ROI You Can Measure

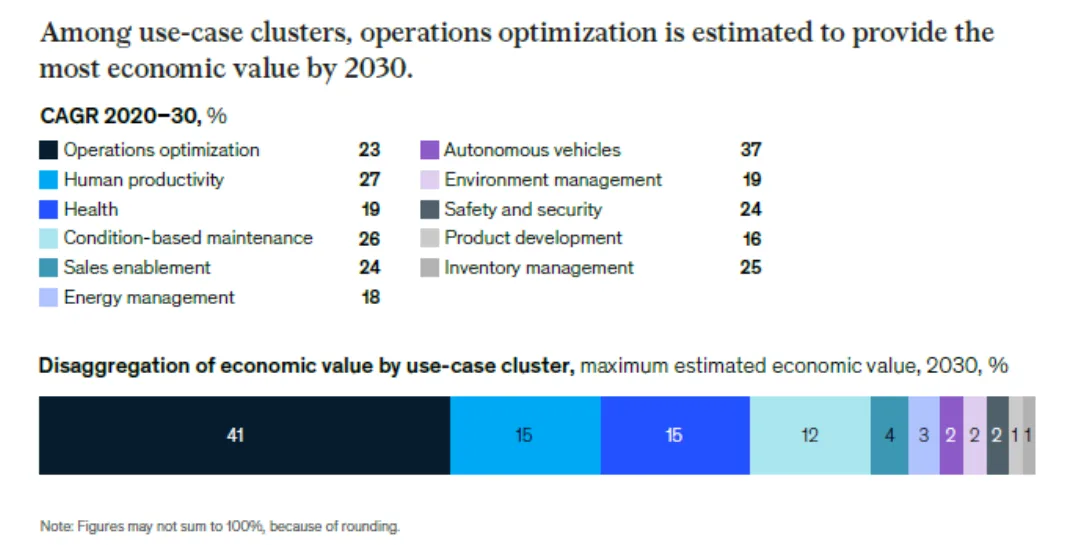

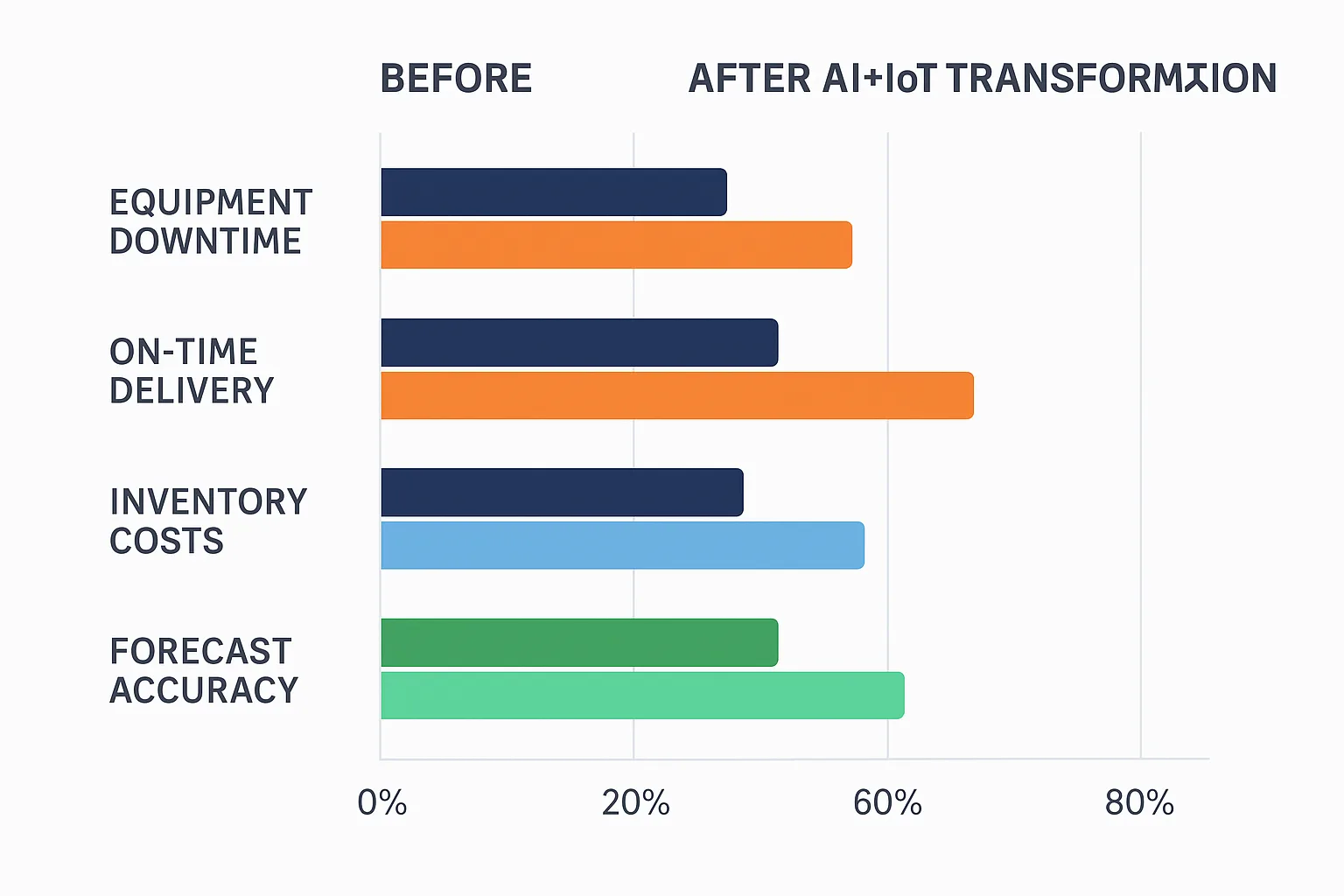

Companies adopting AI-powered supply chain solutions see tangible gains:

- 30–50% Equipment Downtime Reduction with predictive maintenance

- 10–15% Boost in On-Time Deliveries via intelligent routing

- 20–30% Lower Inventory Costs through dynamic stock management

- 20%+ Better Forecast Accuracy, reducing overproduction and waste

These outcomes don’t just improve operations—they elevate customer experience and profitability.

Strategic Advantages for Early Adopters

Firms that act now on AI and IoT in supply chain initiatives gain:

- Faster Crisis Response with real-time visibility and alerts

- Deeper Supplier Collaboration via shared sensor data and dashboards

- Higher Customer Satisfaction from better fulfillment and quality

- Brand Differentiation through innovation and operational excellence

Being proactive isn’t just smart—it’s essential in the digital economy.

Roadmap to Scalable Success

Follow this phased approach for successful implementation:

- Select a High-Impact Use Case – such as predictive maintenance or inventory forecasting.

- Pilot the Solution – Run small tests, gather KPIs, and fine-tune.

- Integrate – Connect outputs to existing SCM, ERP, or MES platforms.

- Train Teams – Ensure staff understand and trust AI-driven insights.

- Scale Across Operations – Apply learnings to expand benefits enterprise-wide.

Navigating Common Barriers of implementing AI and IoT

Barriers are real—but solvable:

- Data Silos: Unified APIs and middleware bridge legacy systems.

- Security Risks: Leverage zero-trust frameworks and encrypted data flows.

- Cultural Resistance: Involve stakeholders early and showcase early wins.

- Budget Constraints: Use pilot programs to demonstrate ROI and unlock funding.

Strategic planning turns obstacles into opportunities.

Choosing the Right Tech Partner

Look for providers with:

- Supply Chain Expertise – Deep knowledge of manufacturing and logistics

- Interoperability – Smooth integration with your tech stack

- Tailored AI Models – Customizable solutions over generic software

- Scalability & Security – Cloud-native with robust security protocols

The right partner becomes an accelerator for transformation.

Beam Data: Your Partner for Smarter Supply Chains

Beam Data offers a proven path to intelligent, resilient supply chains with:

- AI and IoT Use Cases in Manufacturing built for real-world performance

- Real-Time Dashboards that highlight risks, bottlenecks, and opportunities

- Edge + Cloud Flexibility for real-time responsiveness and scalability

- Client-Proven Results backed by operational and financial KPIs

We bridge ambition and execution to build tomorrow’s supply chain—today.

Ready to build a smarter, more resilient supply chain? Partner with Beam Data to unlock the full potential of AI-powered supply chain solutions and drive value from your existing operations. From predictive maintenance to real-time analytics and AI-driven inventory optimization, Beam Data has helped a diverse range of companies successfully integrate AI and IoT in supply chain strategies.

Every supply chain is unique—so are the challenges it faces. At Beam Data, we don’t believe in one-size-fits-all. Our experts collaborate with your team to design custom intelligent supply chain technologies that align with your goals. Whether you’re optimizing complex logistics networks, deploying edge computing in logistics, or implementing a digital twin and AI supply chain model, we create solutions that adapt to your business—not the other way around.

AI and IoT integration isn’t just a passing trend—it’s the engine powering future-ready supply chains. Companies that embrace these technologies now are creating intelligent ecosystems that can anticipate change, react instantly, and deliver with precision.

The path to resilience starts with vision—and the right partner.

FAQs

What’s the difference between AI and IoT in supply chain use?

IoT collects data via sensors; AI analyzes that data to drive intelligent decisions.

Are these solutions just for large enterprises?

No. Modular platforms and smart scaling make them ideal for SMBs as well.

Can I prove ROI quickly?

Yes. Start with a small, focused pilot—results in inventory savings and downtime reduction typically emerge in months.

Will this integrate with my current systems?

Absolutely. Solutions from Beam Data support SAP, Oracle, and more.

How long to launch a pilot?

Most go live within 90 days, with measurable outcomes in 3–6 months.