Mining operations are essential to the global economy—but they also produce some of the world’s most challenging waste streams. With solid tailings expected to exceed 19 billion tonnes by 2025, mining companies are under increasing pressure to improve how they manage, monitor, and minimize environmental waste. AI waste management mining is emerging as a transformative solution to this challenge. From sorting and classification to predictive modeling and route optimization, AI helps streamline mining waste management systems—delivering greater precision, improved sustainability, and lower long-term costs.

While challenges remain around infrastructure, data quality, and scaling AI effectively, companies that act early are finding opportunities to lead. In this blog, we explore the environmental urgency, the role AI plays in modern waste management, and how mining organizations can begin building smarter, more sustainable practices.

The Mining Waste Challenge: Scale, Impact, and Urgency

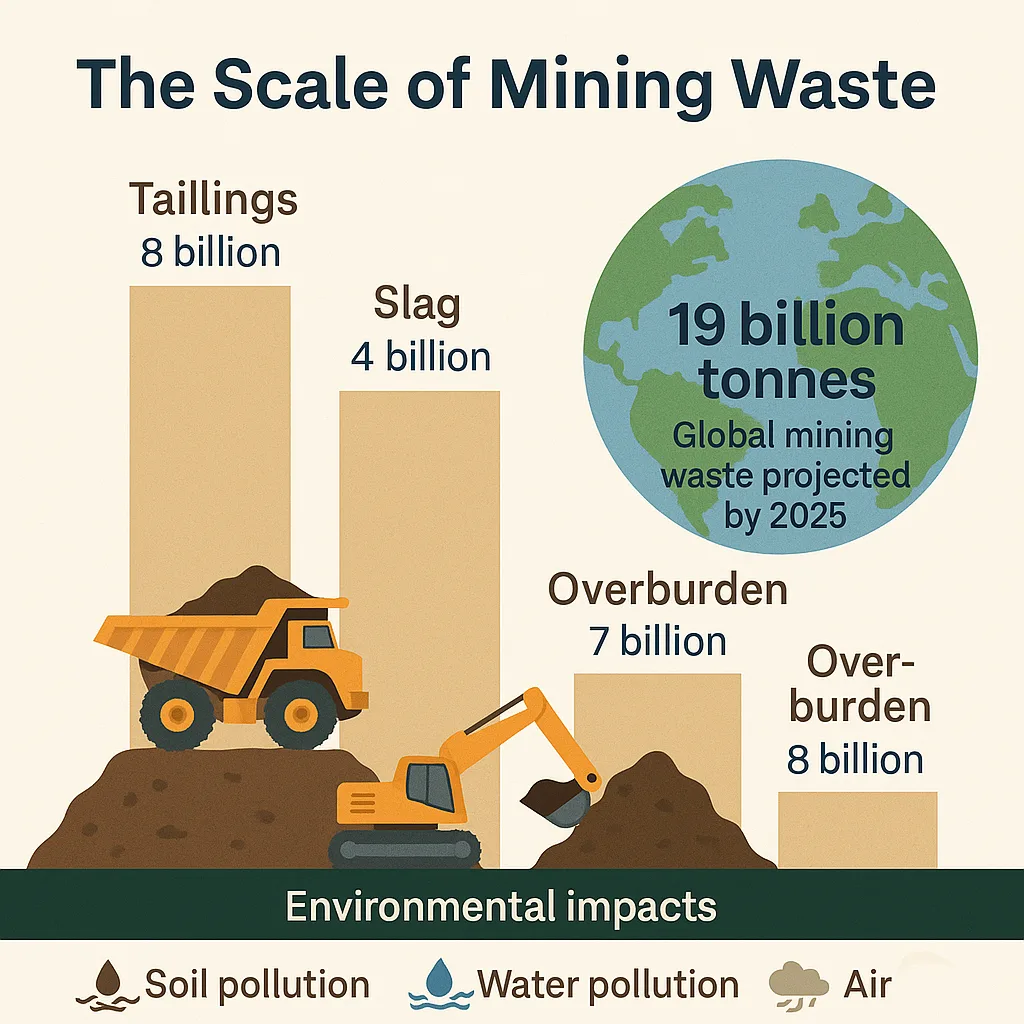

Mining operations generate enormous volumes of waste—including overburden, slag, and tailings—that can pose serious environmental risks if mismanaged. These byproducts often contain toxic substances that can contaminate water supplies, degrade soil, and harm nearby ecosystems.

According to recent forecasts, global tailings volumes are projected to exceed 7 billion tonnes annually, with total mining waste reaching 19 billion tonnes by 2025. As governments tighten environmental regulations and communities demand stronger ESG accountability, the status quo is no longer tenable.

For mining executives and sustainability leads, the message is clear: the environmental cost of inaction is rising—fast. Mining sustainability solutions must now be data-driven, predictive, and AI-enhanced.

Traditional Waste Management Methods: Falling Short of the Moment

Most mining waste is still handled using legacy methods—tailings ponds, landfills, and manual inspection processes. These approaches, while familiar, are increasingly:

- Labor-intensive

- Reactive rather than predictive

- Costly over time

- Insufficiently precise

- Environmentally risky

Without real-time data or intelligent automation, operators may miss early signs of equipment inefficiencies, contamination risks, or waste misclassification—leading to regulatory penalties and increased remediation costs.

How AI Waste Management in Mining is changing the landscape

AI waste management in mining brings a new level of visibility, speed, and intelligence to mining’s environmental operations. It begs the question: What are the AI solutions for mining & how does AI reduce waste? Here are four high-impact areas where AI is already being applied:

A. Smart Sorting & Classification

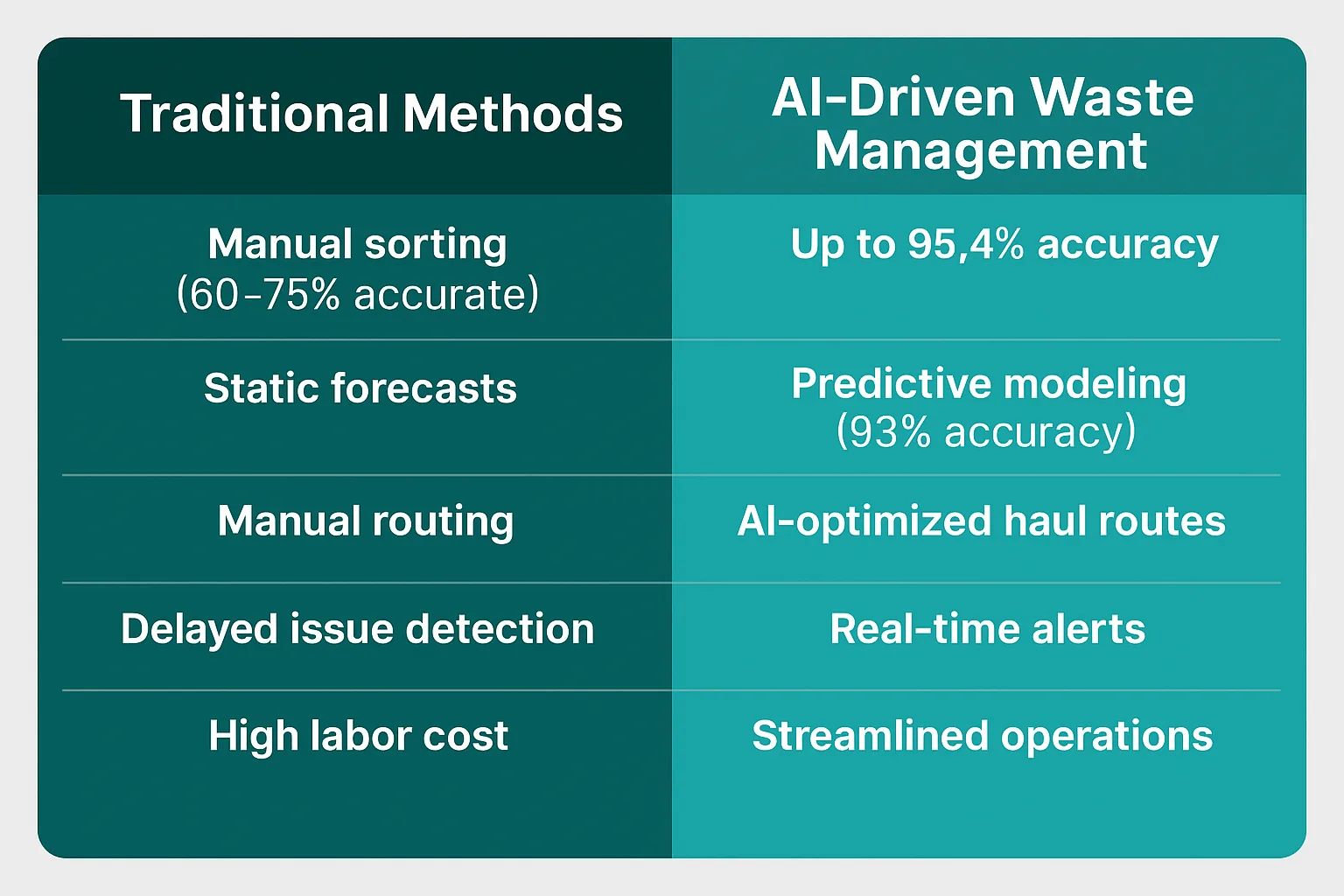

Computer vision and machine learning models can identify different waste types (e.g., metal vs. non-metal, hazardous vs. inert) with up to 95% accuracy, drastically improving material recovery and minimizing landfill overflow.

B. Predictive Analytics for Waste Forecasting

Using operational and sensor data, AI can forecast waste volumes and types based on production inputs, environmental conditions, and historical outputs. These predictive analytics mining waste models help plan disposal, recycling, and treatment capacity ahead of time.

C. Route & Resource Optimization

AI algorithms can optimize how waste is collected, stored, or transported—cutting down on unnecessary fuel usage, reducing emissions, and improving haulage efficiency by 9–12% in some use cases.

D. Smart Monitoring Systems

Sensor-equipped systems (e.g., for tailings dam levels, leachate flows, or fill-rate detection) feed data into AI platforms for continuous monitoring. This enables early intervention before a compliance breach or environmental hazard occurs, supporting AI for environmental compliance across operations.

AI Waste Management vs. Traditional Methods: The Business Case for Change

| Metric | Traditional Approach | With AI |

| Sorting Accuracy | 60–75% (manual) | Up to 95.4% |

| Forecasting Accuracy | Low / static models | Up to 93% |

| Haul Route Efficiency | Manual dispatch | 9–12% fuel savings |

| Environmental Risk Response | After-the-fact | Real-time alerts |

| Labor Intensity | High | Reduced manual workload |

AI doesn’t just modernize waste handling—it repositions it as a strategic driver of cost control, safety, and ESG performance.

Overcoming Adoption Barriers of AI Waste Management in Mining

Despite the promise, many mining leaders hesitate to pursue AI for waste management due to several real concerns:

| Barrier | What It Means |

| Lack of internal AI capacity | Limited technical teams to evaluate or manage AI models |

| Data fragmentation | Inconsistent or siloed data sources across departments |

| Unclear ROI or metrics | Difficulty quantifying benefits or tracking ESG impact |

| Integration challenges | Concerns about compatibility with older infrastructure |

| Budget & resource limits | Hesitation to fund high-CapEx projects without clear pilots |

Fortunately, many of these barriers can be overcome through a phased, strategy-led approach—starting with use case identification and data maturity assessment before moving toward implementation.

Build a Smarter, More Sustainable Future with BeamData

The waste challenge in mining is only growing—but so is the opportunity to address it with intelligence, precision, and measurable impact. So, what is the future of AI in mining industry?

Artificial Intelligence gives mining companies the tools to:

- Improve environmental stewardship

- Meet stakeholder expectations

- Unlock cost savings

- Enhance operational agility

Mining companies that invest in smart mining operations now won’t just reduce their environmental footprint—they’ll increase resilience, build trust, and gain a long-term competitive edge.

This is where BeamData mining innovation plays a vital role. By offering advanced data infrastructure, real-time analytics, and AI-ready platforms, BeamData enables mining companies to extract valuable insights from complex waste data streams, optimize operations, ensure compliance, and transition from linear to circular waste management models. Through its solutions, BeamData empowers the mining sector not just to meet sustainability goals, but to lead in developing smarter, more responsible practices in mineral resource management.

Frequently Asked Questions (FAQ)

1. What types of mining waste can AI help manage?

AI can be applied to manage various types of mining waste, including tailings, slag, overburden, waste rock, and slurry. Machine learning models can be trained to identify, sort, monitor, and forecast these materials based on site-specific conditions and production data.

2. Does AI replace manual labor in waste management?

Not entirely. AI reduces the burden of repetitive, time-consuming tasks like manual sorting or visual inspections, but human expertise remains critical for overseeing operations, validating outputs, and making strategic decisions.

3. How accurate are AI-powered waste classification systems?

Studies show that AI models (like convolutional neural networks or support vector machines) can reach up to 95.4% accuracy in sorting tasks. This dramatically outperforms manual sorting and reduces contamination and landfill overflow.

4. What are the biggest challenges in adopting AI for mining waste?

The top challenges include: fragmented or poor-quality data, integration with legacy systems, high upfront costs, lack of internal AI expertise and site-specific waste variability.

5. How does AI support ESG and sustainability goals?

AI helps companies reduce environmental impact by: preventing contamination through early detection, increasing material recovery and recycling rates, reducing emissions via optimized routing, enhancing compliance with real-time monitoring. It also provides data-backed proof of progress for ESG reporting.

6. Can AI be deployed in remote or legacy mining environments?

Yes, but it requires careful planning. Edge computing devices, wireless sensor networks, and cloud-based platforms can enable AI deployments even in remote or rugged environments. Integration with older systems may require custom engineering or vendor support.

7. What’s the ROI for using AI in mining waste management?

While ROI varies by site, studies have shown:

- 30%+ reduction in maintenance and hauling costs

- Up to 70% fewer waste-related incidents

- 9–12% fuel savings through optimized routing

- Faster regulatory compliance and fewer penalties

Most companies begin to see returns within 6–18 months of targeted implementation.

📩 Let’s Talk with BeamData

If your team is exploring how AI waste management mining could support your environmental or ESG goals, now is the time to act. Whether you’re just starting the journey or ready to scale an existing initiative, the technology—and the impact—is within reach.